01 Pages : 1-14

Abstract

Natural resources as a substitute energy source in recent technological advancements have resulted in the production of biosurfactants. In order to reduce production costs and maximise yield, the current work replaces expensive yeast extract with less expensive substrates and optimises temperature, pH, and agitation. Pseudomonas putida SOL10 produced biosurfactants using a variety of substrates, such as red beans, molasses, whey, potato peels, olive oil, castor oil, crude oil, kerosene oil, and leftover cooking oil. These sources were utilised singly with an inducer, urea. Surface tension and oil displacement assays were used to measure the generation of biosurfactants. The combination of 1% potato peels, 2% leftover cooking oil, and 0.1% urea produced the highest amount of biosurfactant at 30?C, 9.5 pH, and 150 rpm of agitation. There was a drop in surface tension of up to 29 mN/m with a 6.7 cm ODA zone.

keywords

Biosurfactants, Biodegradability, Yeast Extract, Pseudomonas Putida SOL10

Introduction

Surface-active substances called surfactants lessen the tension that exists between two liquids or between a solid and a liquid. Their nature is amphiphilic, meaning they have hydrophobic and hydrophilic moieties with varying degrees of polarity and hydrogen bridges. Ions make up the polar moiety, whereas hydrocarbon chains make up the non-polar moiety (Silva et al., 2014). By making hydrophilic molecules more soluble, they lessen interfacial tensions (Banat et al., 2010). Petroleum is the primary chemical source of surfactants. Unfortunately, it is difficult to degrade these chemically generated surfactants and they are hazardous. Furthermore, hazardous chemicals are formed in soil as a result of the environment's buildup of synthetic surfactants (Kuyukina et al., 2005). Due to these issues, biosurfactants—surfactants that are easily metabolised and environmentally benign—are synthesised (Vijayakumar & Saravanan, 2015). Owing to their remarkable qualities, they are extensively employed in numerous industries, such as food, cosmetics, fertiliser, mining, agrochemicals, and many more.

Because they are more biodegradable, digestible, and biocompatible than chemical surfactants, biosurfactants offer a number of benefits over them. Their structural variety is demonstrated by the dependence of their formation on microorganisms, accessible substrate, and culture circumstances. The primary producer of biosurfactants is bacteria, with a small amount of yeast and fungi also participating (Kitamoto et al., 2002). The three main roles of biosurfactants are to increase the surface area and solubilize hydrophobic substrates to change their characteristics and make them more bioavailable. Additionally, they deal with the adhesion and removal of microbes from surfaces.

Biosurfactant molecules assemble to form bilayers, vesicles, and micelles when the concentration is above CMC. The reason why biosurfactant promotes the solubility and bioavailability of hydrophobic substances is that it reduces surface and interfacial tension through the creation of micelles (Whang et al., 2008). According to Tahhan et al. (2000), biosurfactants can influence how hydrophobic the bacterial cell surface is. Lipopolysaccharide is released at low concentrations of rhamnolipid, increasing the hydrophobicity of the cell surface. The physiological function of biosurfactants in microorganisms is to lower the surface tension of water-impermeable substrates, promoting the growth of microbes on them and increasing their accessibility to the substrate (Fakruddin, 2012).

Through cell adhesion, biosurfactants also play a physiological role in the antibacterial activity of microbes, which helps to stabilise the organisms in harsh environments. Biosurfactant manufacture involves a wide range of microorganisms. According to Bodour et al. (2003), marine bacterial strains cultured on hydrocarbons have the capacity to produce biosurfactants. Less harmful and less degradable biosurfactants are produced by soil microorganisms.

Biosurfactants are divided into four categories based on their microbial origin and chemical structure: glycolipids, phospholipids, polymeric, and particle biosurfactants. Rhamnolipids are the best glycolipids produced by the Pseudomonas species. Trehalose lipids were created by Arthrobacter sp., Nocardia sp., Rhodococcus sp., and Mycobacterium sp., while mannosyl erythritol lipids were formed by pseudozyma Antarctica. According to Shekhar et al. (2015), Ustilago maydis produced cellobiolipids, whereas Candida sp produced sophorolipids.

The most prevalent glycolipid biosurfactant, rhamnolipids are mostly made by Pseudomonas species. Pyolipic acid is the term given to this oily glycolipid, which has L-rhamnose and b-hydroxy decanoic acid as its structural constituents (Henkel et al., 2012). Rhamnose molecules fuse with one or two B-hydroxy 3-hydroxy fatty acids to form rhamnolipids (Banat et al., 2000). Rhamnolipids are classified into four groups based on the length of their chains: mono-rhamnolipid (Rh1), di-rhamnolipid (Rh2), tri-rhamnolipid (Rh3), and tetra-rhamnolipid (Rh4).

Owing to their capacity to reduce surface tension and their biological compatibility, biosurfactants find extensive application in a variety of industries, including food, biodegradation, oil recovery, bioremediation, and pharmaceuticals (Cameotra and Makkar, 2004; Banat et al., 2010b). The utilisation of renewable substrates for the synthesis of biosurfactants has received a lot of interest. Certain inexpensive substrates serve as both a growing medium for microorganisms and aid in the isolation of those that create biosurfactants, like soybean oil (Lee et al., 2008). The production of biosurfactants in industries has been improved through the use of cost-effective substrates, suitable fermentation technology, and strain selection (Marchant & Banat 2012b; Marchant et al., 2014).

2014; Marchant et al. Large-scale manufacturing has not been accomplished at a cost-effective level because of the high-cost input for the recovery and purification of microbial surfactant and the low yield of biosurfactant (Rodrigues et al., 2006; Rodrigues et al., 2006; Smyth et al., 2010). Thus, employing renewable substrates to lower the cost of producing biosurfactants is essential (Banat et al., 2000; Makkar et al., 2011). Strains that can use inexpensive substrates to boost biosurfactant amount and quality could help get beyond these obstacles (Wisjnuprapto et al., 2011). In order to produce biosurfactants with various structures depending on the content of the substrate, a range of different carbon and nitrogen sources have been utilised.

Using low-cost substrates, selecting the strain that produces the most biosurfactant, and adjusting the culture are all key components of a successful strategy to achieve maximal biosurfactant production (Satpute et al., 2008). According to Abalos et al. (2001), the most often utilised substrates for the synthesis of biosurfactants include leftover frying oil, whey waste, soap stock, molasses, olive oil effluents, and fatty acids. When combined with a minimum medium, molasses can serve as a good supply of carbon and aid in Bacillus cultures' synthesis of lipopeptide biosurfactant. When cheese whey and molasses were used as a substrate, Bacillus species produced biosurfactants (Joshi et al., 2008). Wastewater from the dairy industry contains fats and oils (Cammarota & Freire, 2006). According to Daverey & Pakshirajan (2009), these bioproducts are used in conjunction with sugarcane and soybean molasses.

Material And Methods

The current investigation was carried out at Quaid-i-Azam University in Islamabad's Department of Microbiology. The following lists the supplies and methodology employed in the current investigation.

Microorganisms

The live Pseudomonas putida SOL10 bacterial isolates used in this investigation were obtained from the Microbiology Research Lab. These isolates were first obtained from contaminated soil at the Fimkessar oil field in Chakwal, Pakistan (Malik et al., 2013). The bacterial culture was maintained for a brief period of time at 4 °C on nutrient agar slants after being regularly grown on nutrient agar plates to purify it. A 30% glycerol broth was made and stored at -20 °C for long-term preservation.

Chemicals, solvents

Mineral salt medium was the medium employed in this investigation (MSM). Table 3.1 lists its ingredients. The Merk Company's nutrient agar was used to cultivate the bacterium. For the Oil Displacement Assay analysis, crude oil was utilised. Ethyl acetate was utilised in the biosurfactant extraction process. Analytical grade chemicals and medium composition were used.

Analytical methods

The production medium's cell-free supernatant was analysed using surface tension (SFT) and the oil displacement assay (ODA).

Oil displacement assay

The diameter of the generated zone was used to analyse the amount of biosurfactant production. This approach created a thin layer on the water's surface by pouring 40 millilitres of distilled water into a Petri plate and then adding 20 microliters of crude oil to the centre of the surface

Surface tension measurement

The Whilemey plate method was utilized to evaluate surface tension using cell-free supernatant. This device reports surface tension reduction in cell-free broth, where greater reduction corresponds to increased biosurfactant production. Surface tension less than 40 mN/m indicates the production of biosurfactants.

Screening of Different Carbon and Hydrocarbon Sources for Biosurfactant Production

By screening a variety of carbon sources, such as molasses (M), red beans (R.B.), potato peels (P.P.), whey (W), and kerosene oil (K.O.), as well as hydrocarbon sources, such as olive oil (O.L.), castor oil (C.O.), crude oil (C.D.), and waste cooking oil (W.C.O.), biosurfactant formation was found. These sources of hydrocarbons and carbon are widely accessible. Initially, the synthesis of biosurfactants was assessed using these carbon sources separately. Following that, they were employed in various configurations of hydrocarbon and carbon sources to determine the optimal substrate combination that produced a high level of biosurfactant production. Inducers, such as urea, were also employed to improve the outcomes. A mineral salt medium was used for the shake flask fermentation experiments.

Culture Conditions

Shake flask fermentation was used to screen various hydrocarbon and carbon sources in order to produce biosurfactants. Shake flask experiments with carbon/hydrocarbon sources, nitrogen sources, and mineral salt medium (MSM) supplementation were carried out in 250 Erlenmeyer flasks. The mineral salt medium's composition is listed in Tables 3.1 and 3.2 below. The pH was varied up to 7.0 ± 0.2, and the optimal pH was chosen by adjusting a range of pH values. Following that, Pseudomonas putida SOL10 was added to the production medium and it was autoclaved. To create the inoculum, separate colonies of the strain were taken from recently manufactured nutrient agar plates and inoculated in 100 millilitres of nutrient broth. After that, the flask with the inoculum was placed in a shaking incubator at 30 °C for two days. Eppendorf tubes (2 ml) containing 5% of the inoculum were centrifuged for 15 minutes at 12,000 rpm. At the base of palletized Eppendorf was created, collected, and then mixed with distilled water before being moved into flasks containing the production medium.

Optimization of Substrate

Selection of substrate

single-use carbon sources were employed at 2% (2g per 100 ml) concentration, including red beans, potato peels, whey, and molasses. These sources of hydrocarbons and carbon were all readily accessible

Impact of inducer

Because inducers increase the production of biosurfactants, they have a significant effect on it. In this work, we employed 0.1g of urea as an inducer in 100 ml of media containing 2g of substrate. Utilising 2g of substrate with 0.1% of urea in a ratio of red beans (2:1), molasses (2:1), potato peels (2:1), whey (2:1), yeast extract (2:1), olive oil (2:1), kerosene oil (2:1), castor oil (2:1), crude oil (2:1), and leftover cooking oil (2:1), all carbon and hydrocarbon sources were combined with urea.

Combination of carbon and hydrocarbon source

When urea was added to carbon sources separately, red beans produced more biosurfactants than other carbon sources. Therefore, with a concentration of 2% oil 1% red beans and 0.1% urea, we combined red beans with all hydrocarbon sources. Since olive oil is not cost-effective, we decided to move forward with our studies using waste cooking oil instead of olive oil, which produced better results in this experiment.

Waste cooking oil demonstrated the highest production when combined with all carbon sources, such as red beans, molasses, potato peels, and whey, at a concentration of 2% waste cooking oil with 1% carbon source and 0.1% urea (2:1:0.1). This was the case for hydrocarbon sources used alone with urea. Following that, the optimal mixture was chosen, and various oil concentrations were tested along with carbon sources and urea (1:1:0.1, 2:1:0.1, and 3:1:0.1).

Temperature optimization

Cultivation was done in 250 ml flasks in a shaking incubator at various temperatures (25?C, 30?C, 37?C, and 50?C) in order to optimise temperature.

pH optimization

After that, the strain was exposed to pH optimisation by shake flask fermentation, which combined an ideal substrate combination with an ideal temperature. First, the manufacturing medium's pH range varied and was 3, 5, 7, 9, and 11.

Agitation optimization

Different agitation speeds (0 rpm, 100 rpm, and 150 rpm) were used during the cultivation process in a shake flask experiment with optimised substrate mixture, temperature, and pH.

Extraction of biosurfactant

In order to precipitate glycolipids, 96-hour-old cells were placed in broth, acidified with phosphoric acid to a pH of 2, and then refrigerated overnight at 4?C for the purpose of biosurfactant extraction. Subsequently, three extractions of around 20 ml of broth-containing cells were made in a separating funnel using an equal volume of ethyl acetate.

Two layers formed with the addition of ethyl acetate to the broth: an organic layer on top that contains biosurfactant. The organic layer was taken off and allowed to evaporate at room temperature in order to produce crude biosurfactant

Fourier Transform Infrared Spectroscopy

The method uses the absorption of various infrared light frequencies to analyse the existence of a functional group in molecules. In this work, the chemical makeup of crude biosurfactant was examined using a Tensor 27 (Bruker) FTIR spectrophotometer fitted with ZnSe ATR.

Table 1

Typical composition of trace elements solution used at a conc. 0.1 ml per litre of the MSM (i.e. production medium) in this study

|

Chemical constituent |

Quantity

(g L-1) |

|

ZnSO4.7H2O |

2.32 |

|

MnSO4.4H2O |

1.78 |

|

H3BO3 |

0.56 |

|

CuSO4.5H2O |

1 |

|

NH4MoO4.2H2O |

0.39 |

|

KI |

0.66 |

Results

Biosurfactants are produced worldwide for many purposes as they replace chemical surfactants that are too costly. Moreover, they show properties including less toxicity, and their biodegradable nature and hence used in place of chemical surfactants. In this study, different carbon and hydrocarbon sources were evaluated as substrates for increased biosurfactant production by Pseudomonas putida SOL 10. The purpose of this study was to select the best cost-effective substrate for maximum biosurfactant production.

Different analytical techniques were used for the analysis of biosurfactant production by Pseudomonas putida SOL 10. These techniques were surface tension (SFT) and oil displacement assay (O.D.A). Another analysis was Fourier Transform Infrared spectroscopy (FTIR).

Effect of different carbon and hydrocarbon sources on biosurfactant production by Pseudomonas putida SOL 10

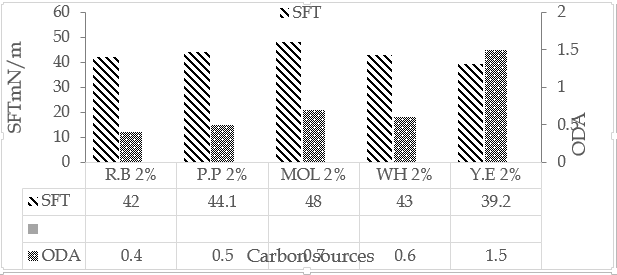

These all were used individually at 2% (2g/100 ml) concentration as a substrate for biosurfactant production. Among carbon sources, red beans showed some better results as compared to others with SFT 42 mN/m and ODA 0.4 cm (Fig 4.1) whereas Pseudomonas putida SOL 10 when grown on hydrocarbon sources better results was shown by olive oil with oil displacement of 1cm and surface tension reduction upto SFT 38.3 mN/m. Yeast was used as control. (Fig 4.2)

Effect of urea as inducer on the production of biosurfactant

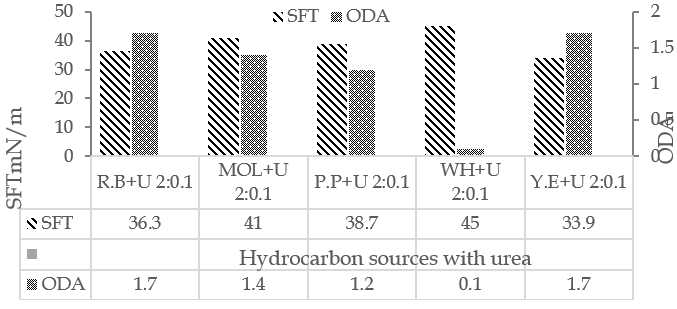

Inducers have a great impact on biosurfactant production. In this study, urea was used as an inducer to check its effect on enhanced biosurfactant production. Carbon and hydrocarbon sources after their individual analysis, urea was used in combination with all substrate sources with 0.1% (0.1g/100 ml) concentration of urea with 2% carbon (2g in 100 ml) and 2% (2g in 100 ml) hydrocarbon sources. On carbon sources, Pseudomonas putida SOL10 showed enhanced production on red beans in combination with urea (2:0.1) as other carbon sources also show reduction in surface tension when used with urea but red beans show significant reduction of surface tension from 42 mN/m (singly) to 36.3 mN/m (in combination with urea) and ODA value from 0.4 (singly) to 1.7 (combination with urea). Potato peels reduced SFT up to 38.7 mN/m with an ODA value of 1.2 cm, while molasses and whey showed surface tension reduction values of 41 mN/m and 45 mN/m and gave ODA 1.4 cm and 0.1 cm. The yeast extract that was used as a control gave 1.7 cm ODA and 33.9 mN/m SFT values. So this shows that urea addition has a positive influence on biosurfactant production (Fig 4.3)

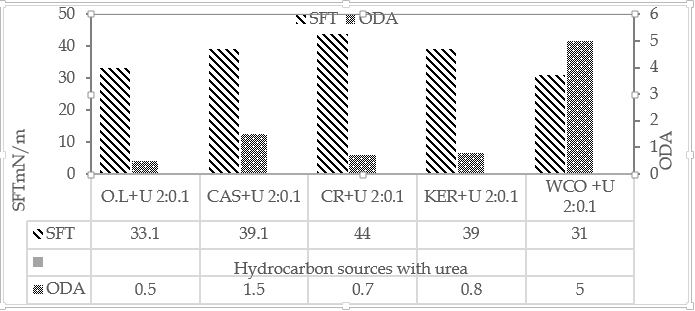

Among hydrocarbon sources, the best results were shown by waste cooking oil (WCO+U 2:0.1) with a maximum reduction of SFT from 51 mN/m (singly) to 31 mN/m (combination) and ODA values from 0.1 cm (singly) to 5 cm (combination). Olive oil also showed a significant reduction from 38.3 mN/m to 33.1 mN/m and Oil displacement of 0.1 cm. Values of SFT and ODA were 47.7 mN/m and 1.6 cm in the case of castor oil, 48.1 mN/m and 3.5 cm in crude oil while in kerosine oil 44.6 mN/m SFT and 0.1 cm ODA values were observed. As olive oil is not cost-effective we used waste cooking oil for further analysis. (Fig 4.4)

It was observed that in the previous analysis, red beans and waste cooking oil when used in combination with urea gave better results so these two substrates were used in different combinations for further analysis

Effect of different hydrocarbon sources in combination with red beans and urea as inducer

In the previous analysis, red beans showed the best results at 2% concentration along with urea 0.1% (R.B+U 2:0.1). In order to check the effect of red beans in combination with hydrocarbon sources along with urea, we used 1% red beans in combination with olive oil, kerosene oil, castor oil, crude oil and waste cooking oil at 2% concentration along with 0.1% urea. It was observed that when Pseudomonas putida SOL10 was grown in combination with OIL+R.B+U (2:1:0.1), maximum reduction in surface tension was shown by olive oil in combination with red bean and urea (O.L+R.B+U 2:1:0.1). SFT reduction was up to 32 mN/m with highest oil displacement of 7cm. Waste cooking oil (WCO+R.B+U 2:1:0.1) also showed significant results with an SFT value of 34mN/m and ODA 3.6 cm while a 6 cm ODA zone was observed at 2:1:0.1 (K.E+R.B+U) with SFT reduction up to 35mN/m. However, results showed by crude (CR+R.B+U 2:1:0.1).

Effect of different carbon sources in combination with waste cooking oil and urea as inducers on biosurfactant production

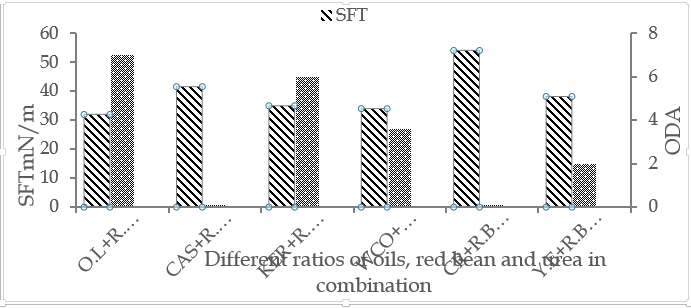

waste cooking oil was used in combination with all carbon sources red beans, molasses, potato peels and whey. 2% waste cooking oil was used in combination with 1% of all carbon sources along with 0.1% urea (WCO+CARBON SOURCE+U 2:1:0.1). All of these combinations gave significant results but the best results were shown by potato peels and red beans. Pseudomonas putida SOL10 showed increased biosurfactant production on waste cooking oil in combination with potato peels and urea (WCO+P.P+U 2:1:0.1) with surface tension reduction up to 29 mN/m showed maximum oil displacement of 6.3 cm. A combination of red beans with waste cooking oil along with urea (WCO+R.B+U 2:1:0.1) also gave significant results of oil displacement of 5.3 cm and SFT reduction up to 31 mN/m. On the other hand, SFT values of whey (WCO+WH+U 2:1:0.1) and molasses (WCO+MOL+U 2:1:0.1) were 34.3 mN/m and 36 mN/m with ODA values of 3 cm and 2.4 cm respectively and gave a bit good results but not that much as compare to red beans and potato peels. Yeast extract used in combination with waste cooking oil (WCO+Y.E+U 2:1:0.1) showed analytical values of ODA 5 cm and SFT 30 mN/m. (Fig 4.6)

Effect of different concentrations of waste cooking oil in combination with red bean along with urea on biosurfactant production

Three combinations were made that were (2% WCO+1% R.B+0.1% U), (3% WCO+1% R.B+0.1% U), and (4% W.C.O+1% R.B+0.1% U). Among them, maximum biosurfactant production was shown by a 2% waste cooking oil combination (WCO+R.B+U 2:1:0.1) with surface tension reduction up to 31 mN/m and oil displacement of 5.6 cm. On the other hand, less reduction in surface tension was shown at 3% i.e SFT 36 mN/m, ODA 1 cm and further less reduction at 4% i.e. SFT 44 mN/m, ODA 0.8 cm of waste cooking oil combinations which shows decreased biosurfactant production by increasing concentration of waste cooking oil. (Fig 4.7)

Effect of different concentrations of waste cooking oil in combination with potato peels along with urea on biosurfactant production

Pseudomonas putida SOL10 was grown on different concentrations of waste cooking oil with potato peels along with urea. 2%, 3% and 4% waste cooking oil was used in combination with 1% potato peels and 0.1% urea. Among them, maximum production was shown by 2% waste cooking oil (WCO+P.P+U 2:1:0.1) with SFT 29 mN/m and the highest ODA up to 6.3 cm.

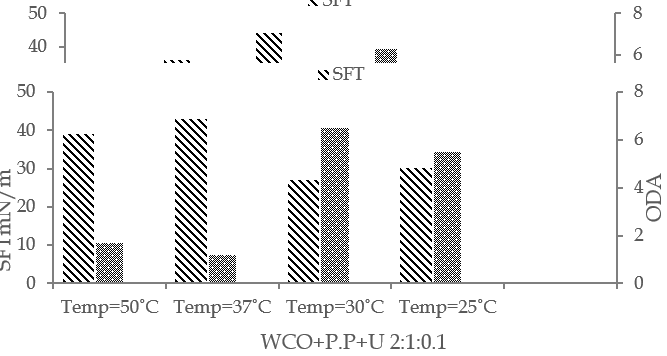

Effect of different temperatures on waste cooking oil in combination with potato peels along with urea on biosurfactant production

Pseudomonas putida SOL10 was further investigated for the effect of temperature on its biosurfactant production. Different temperature range was selected (25?C, 30?C, 37?C, 50?C) in order to check the biosurfactant abilities of SOL-10. It was found that maximum production occurred at 30?C with SFT 28 mN/m and ODA 6.1cm whereas significant results were also observed at 25?C with 30.3 mN/m SFT and 5.5cm ODA values.

Effect of different pH on waste cooking oil in combination with potato peels along with urea on biosurfactant production

The cultivation broth showed maximum production at 30?C and was subjected to different pH ranges (3, 5, 7, 9, and 11). Among them, maximum production was achieved at two pH values including pH 7 with SFT 28.2 mN/m, ODA 5.2 cm and surface tension reduction up to 28 mN/m was observed at pH 9 with ODA 4.8 cm. At pH 3, 5 and 11 little reduction in SFT was observed with 47 mN/m SFT and 0.8 cm ODA at pH 3, 36.3 mN/m SFT and 3 cm ODA at pH 5 and 34.4 mN/m SFT and 3.5 cm ODA at pH 11. However in order to get the best pH value, different pH range was selected (5, 5.5, 6, 6.5, 7, 7.5, 8, 8.5, 9, 9.5 and 10) wherein pH 9.5 achieved maximum production with SFT 28 mN/m and highest Oil displacement zone of 6.7 cm. (Fig 4.9)

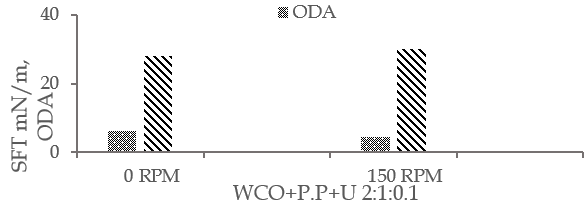

Effect of different agitation speeds on waste cooking oil combination with potato peels along with urea on biosurfactant production

Optimized media was then subjected to different agitation speeds (0 rpm, 150 rpm). Pseudomonas putida SOL10 produce maximum biosurfactant at 150 rpm, as SFT values for 0 rpm (30.5 mN/m) and 150 rpm (28 mN/m) were almost the same but the maximum ODA value was achieved at 150 rpm (6.2 cm) as compared to 0 rpm (2cm) (Fig 4.10).

Figure 1

Effect of different 2% carbon sources P.P (potato peels), R.B (red beans), M (molasses) and Y.E (yeast extract) on biosurfactant production Pseudomonas putida SOL10

Figure 2

Effect of 2% hydrocarbon sources Olive oil (O.L), Castor oil (C.O), Crude oil (CR.O), Kerosene oil (K.O) and Waste cooking oil (W.C.O) on biosurfactant production by Pseudomonas putida

Figure 3

Effect of different 2% carbon sources along with 0.1% urea on biosurfactant production by Pseudomonas putida SOL10

Figure 4

Effect of combination of 2% hydrocarbon sources with 0.1% urea on biosurfactant production by Pseudomonas putida SOL10

Figure 5

Effect of combination of 2% Hydrocarbon source, 1% Red beans and 0.1% Urea on biosurfactant production by Pseudomonas putida SOL10

Figure 6

Effect of combination of 2% Waste cooking oil, 1% carbon source and 0.1% urea on biosurfactant production by Pseudomonas putida SOL10

Figure 7

Effect of combination of potato peels and red beans with different concentrations of Waste cooking oil and urea on biosurfactant production by Pseudomonas putida SOL10

Figure 8

Effect of combination of waste cooking oil, potato peels and urea at different temperatures on biosurfactant production by Pseudomonas putida SOL10

Figure 9

Effect of combination of waste cooking oil, potato peels and urea at different pH on biosurfactant production by Pseudomonas putida SOL10

Figure 10

Effect of combination of waste cooking oil, potato peels and urea at different agitation on biosurfactant production by Pseudomonas putida SOL10

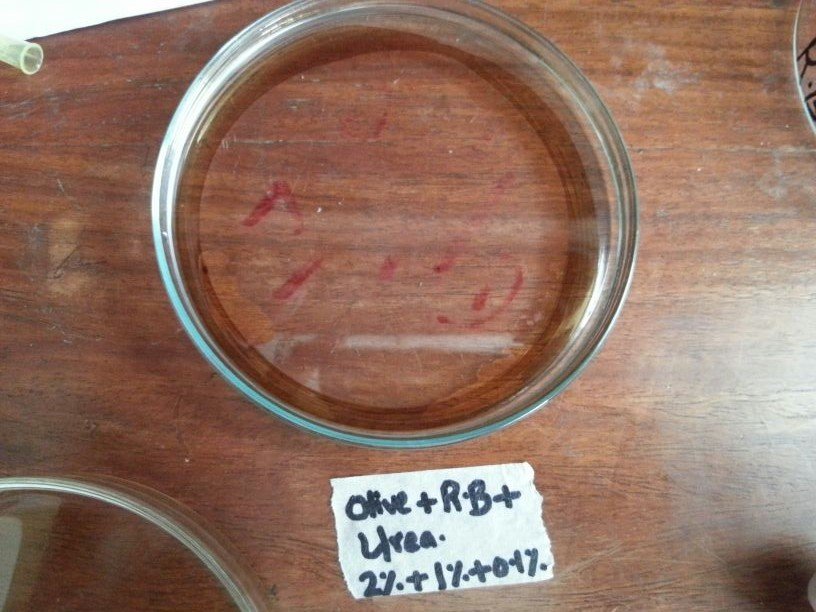

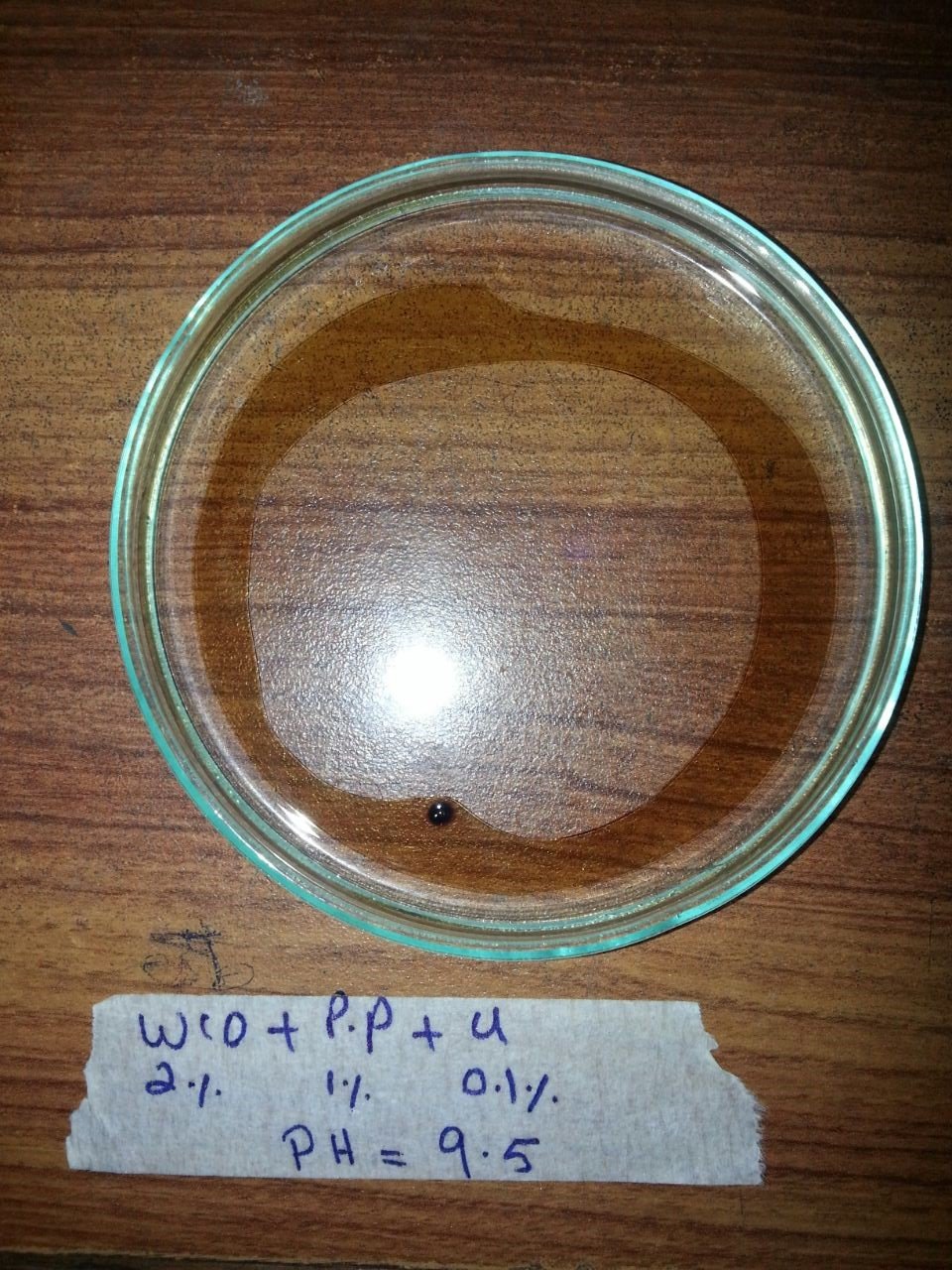

Figure 11

Oil displacement showed in combination of WCO+P.P+U (2:1:0.1) at pH 9.5

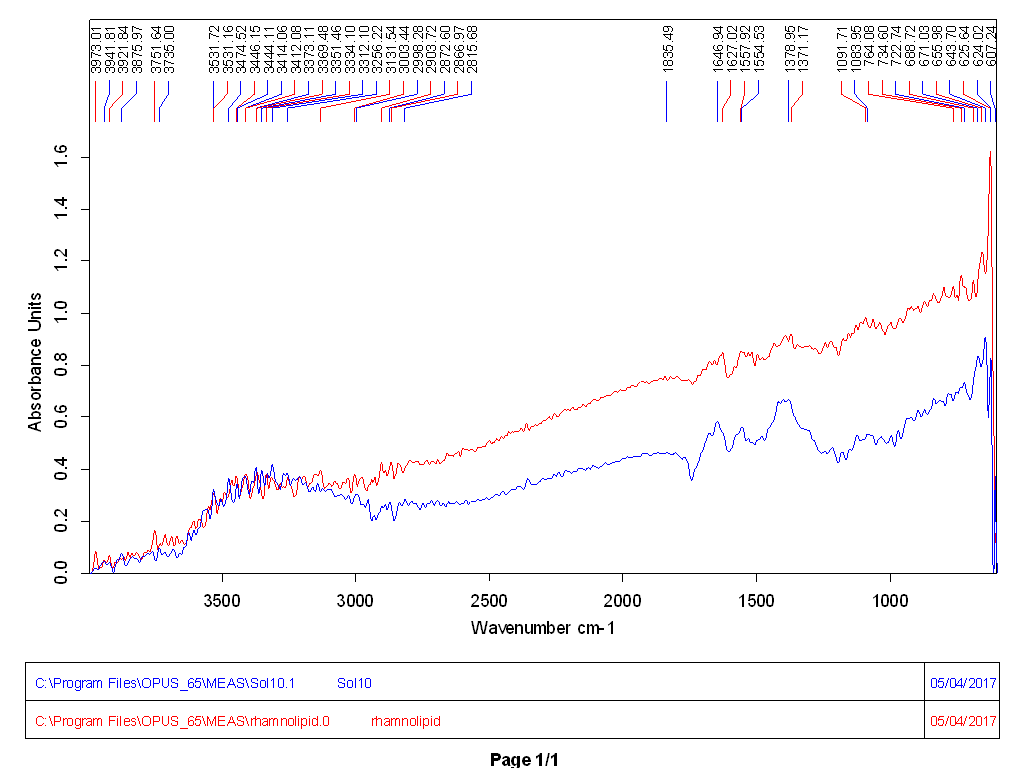

Fourier Transformed Infrared Microscopy

IR spectrum of crude biosurfactant obtained from Pseudomonas putida SOL10 revealed presence of rhamnolipid biosurfactant. Spectrum of crude biosurfactant and standard rhamnolipid were examined and compared. The FTIR spectrum of crude biosurfactant and standard is shown in Fig 4.12. The red line represents the standard rhamnolipid while blue line represents sample. From figure we observed different functional groups peaks with different intensity. Absorption peak at 3256.22 cm-1 – 3521.72 cm-1 gave indication of OH group of rhamnolipids.

Figure 12

FTIR spectra of crude rhamnolipid by Pseudomonas putida SOL10 (blue) and IR spectra of standard rhamnolipid (red).

References

- Bodour, A. A., Drees, K. P. & Maier, R. M. (2003) ‘Distribution of biosurfactantâ€producing bacteria in undisturbed and contaminated arid Southwestern soils.’, Applied and environmental microbiology. American Society for Microbiology, 69(6), pp. 3280–7. https://doi.org/10.1128/AEM.69.6.3280-3287.2003

- Cammarota, M. C. & Freire, D. M. G. (2006) ‘A review on hydrolytic enzymes in the treatment of wastewater with high oil and grease content’, Bioresource Technology, 97(17), pp. 2195–2210. https://doi.org/10.1016/j.biortech.2006.02.030

- Daverey, A., & Pakshirajan, K. (2009) ‘Production, Characterization, and Properties of Sophorolipids from the Yeast Candida bombicola using a Lowâ€cost Fermentative Medium’, Applied Biochemistry and Biotechnology. Humana Press Inc, 158(3), pp. 663–674. https://doi.org/10.1007/s12010-008-8449-z.

- Henkel, M., Müller, M. M., Kügler, J. H., Lovaglio, R. B., Contiero, J., Syldatk, C., & Hausmann, R. (2012a) ‘Rhamnolipids as biosurfactants from renewable resources: Concepts for nextâ€generation rhamnolipid production’, Process Biochemistry. Elsevier Ltd, 47(8), pp. 1207–1219. https://doi.org/10.1016/j.procbio.2012.04.018

- Kuyukina, M. S., Ivshina, I. B., Makarov, S. O., Litvinenko, L. V., Cunningham, C. J., & Philp, J. C. (2005) ‘Effect of biosurfactants on crude oil desorption and mobilization in a soil system’, Environment International, 31(2), pp. 155–161. https://doi.org/10.1016/S1389-1723(02)80149-9. https://doi.org/10.1016/j.envint.2004.09.009.

- Makkar, R. S., Cameotra, S. S., & Banat, I. M. (2011) ‘Advances in utilization of renewable substrates for biosurfactant production.’, AMB Express, 1(1), p. 5. https://doi.org/10.1186/2191-0855-1-5

- Qazi, M. A., Malik, Z. A., Qureshi, G. D., Hameed, A. and Amed, S. (2013) ‘Yeast Extract as the Most Preferable Substrate for Optimized Biosurfactant Production by rhlB Gene Positive Pseudomonas putida SOLâ€10 Isolate’, Journal of Bioremediation & Biodegradation, 4(7), pp. 1–10. doi: 10.4172/2155â€6199.1000204.

- Rodrigues, L., Banat, I. M., Teixeira, J., & Oliveira, R. (2006) ‘Biosurfactants: potential applications in medicine’, Journal of Antimicrobial Chemotherapy. Oxford University Press, 57(4), pp. 609–618. https://doi.org/10.1093/jac/dkl024.

- Saravanan, V. and Vijayakumar, S. (2015) ‘Production of biosurfactant by Pseudomonas aeruginosa PB3A using agro†industrial wastes as a carbon source’, Malaysian Journal of Microbiology, 10(1), pp. 57–62. https://doi.org/10.1016/j.biotechadv.2010.02.006.

- Satpute, S. K., Banat, I. M., Dhakephalkar, P. K., Banpurkar, A. G., & Chopade, B. A. (2010) Biosurfactants, bioemulsifiers and exopolysaccharides from marine microorganisms’, Biotechnology Advances, 28(4), pp. 436–450.

- Satpute, S. K., Bhawsar, B. D., Dhakephalkar, P. K. and Chopade, B. A. (2008) ‘Assessment of different screening methods for selecting biosurfactant producing marine bacteria. IJMS 37(3) [September 2008]. CSIR.

- Shekhar, S., Sundaramanickam, A., & Balasubramanian, T. (2015) ‘Biosurfactant Producing Microbes and their Potential Applications: A Review’, Critical Reviews in Environmental Science and Technology, 45(14), pp. 1522–1554. https://doi.org/10.1080/10643389.2014.955631.

- Whang, L. M., Liu, P. W. G., Ma, C. C., & Cheng, S.â€S. (2008) ‘Application of biosurfactants, rhamnolipid, and surfactin, for enhanced biodegradation of dieselâ€contaminated water and soil’, Journal of Hazardous Materials, 151(1), pp. 155–163. https://doi.org/10.1016/j.jhazmat.2007.05.063

Cite this article

-

APA : Umar, A., Aslam, S., & Ahmed, S. (2023). Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates. Global Drug Design & Development Review, VIII(IV), 1-14. https://doi.org/10.31703/gdddr.2023(VIII-IV).01

-

CHICAGO : Umar, Aiman, Sadia Aslam, and Safia Ahmed. 2023. "Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates." Global Drug Design & Development Review, VIII (IV): 1-14 doi: 10.31703/gdddr.2023(VIII-IV).01

-

HARVARD : UMAR, A., ASLAM, S. & AHMED, S. 2023. Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates. Global Drug Design & Development Review, VIII, 1-14.

-

MHRA : Umar, Aiman, Sadia Aslam, and Safia Ahmed. 2023. "Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates." Global Drug Design & Development Review, VIII: 1-14

-

MLA : Umar, Aiman, Sadia Aslam, and Safia Ahmed. "Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates." Global Drug Design & Development Review, VIII.IV (2023): 1-14 Print.

-

OXFORD : Umar, Aiman, Aslam, Sadia, and Ahmed, Safia (2023), "Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates", Global Drug Design & Development Review, VIII (IV), 1-14

-

TURABIAN : Umar, Aiman, Sadia Aslam, and Safia Ahmed. "Optimization of Pseudomonas putida SOL10 Biosurfactant Production Using Cost-Effective Substrates." Global Drug Design & Development Review VIII, no. IV (2023): 1-14. https://doi.org/10.31703/gdddr.2023(VIII-IV).01